-

-

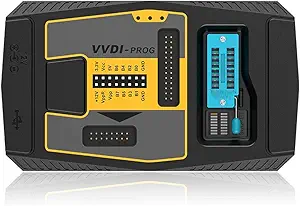

Software Installation: Download and install the latest version of the dedicated software (e.g., Xgpro) from the manufacturer’s or distributor’s website. This is crucial for accessing the full chip database.

-

Hardware Connection: Connect the programmer to your computer’s USB port using the provided cable. The device is powered entirely via USB.

-

Selecting the Chip:

-

Open the software.

-

Use the “Search” or “Select” function to find your target IC. You can search by chip manufacturer, type, or part number (e.g., “ATmega328P”, “W25Q128”).

-

-

Placing the Chip:

-

Lift the lever of the 40-pin ZIF socket.

-

Carefully orient the IC according to the pin-1 diagram printed on the socket.

-

Place the chip into the socket and lock it down by closing the lever.

-

-

Basic Operations:

-

Read: Reads the content of the chip and saves it to a file on your computer (.bin for data, .hex for MCUs).

-

Program: Load a firmware file (.bin, .hex) from your computer and burn it into the chip. The software will automatically erase, program, and verify the chip.

-

Verify: Compares the data on the chip against a file on your computer to check for errors.

-

Erase: Clears the content of the chip.

-

-

Adapter Usage (for non-DIP chips):

-

For SMD chips (SOIC, TSSOP, etc.), you will need separate SOIC8, SOIC16, or other adapters.

-

The adapter plugs into the ZIF socket, and the SMD chip is placed on the adapter’s footprint, often secured with a clip.

-

Quick View

Wishlist

Add to cart-

Software Installation: Download and install the latest version of the dedicated software (e.g., Xgpro) from the manufacturer’s or distributor’s website. This is crucial for accessing the full chip database.

-

Hardware Connection: Connect the programmer to your computer’s USB port using the provided cable. The device is powered entirely via USB.

-

Selecting the Chip:

-

Open the software.

-

Use the “Search” or “Select” function to find your target IC. You can search by chip manufacturer, type, or part number (e.g., “ATmega328P”, “W25Q128”).

-

-

Placing the Chip:

-

Lift the lever of the 40-pin ZIF socket.

-

Carefully orient the IC according to the pin-1 diagram printed on the socket.

-

Place the chip into the socket and lock it down by closing the lever.

-

-

Basic Operations:

-

Read: Reads the content of the chip and saves it to a file on your computer (.bin for data, .hex for MCUs).

-

Program: Load a firmware file (.bin, .hex) from your computer and burn it into the chip. The software will automatically erase, program, and verify the chip.

-

Verify: Compares the data on the chip against a file on your computer to check for errors.

-

Erase: Clears the content of the chip.

-

-

Adapter Usage (for non-DIP chips):

-

For SMD chips (SOIC, TSSOP, etc.), you will need separate SOIC8, SOIC16, or other adapters.

-

The adapter plugs into the ZIF socket, and the SMD chip is placed on the adapter’s footprint, often secured with a clip.

-

-

-

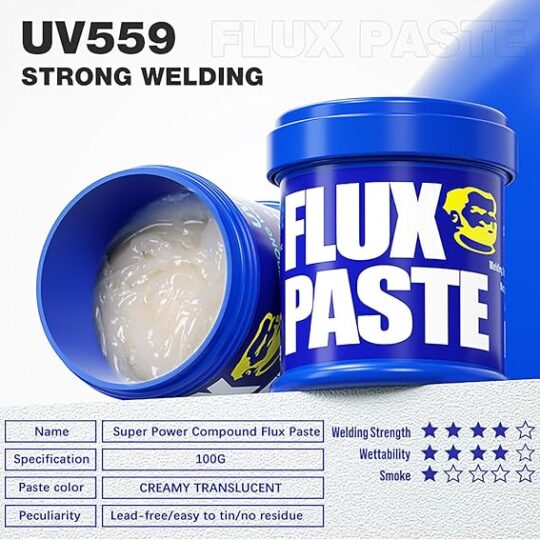

Uv559 Mechanic Soldering Flux Paste Uv559 No Clean Bga Solder Ball Repair Welding Paste For Phone Pcb Pga Smd Rework

Rated 3.50 out of 5-

Brand: Mechanic

-

Model: UV559

-

Type: No-Clean Flux Paste

-

Applications: BGA, SMD, PGA, PCB, Mobile Repair, Laptop Repair

-

Features: Oxidation prevention, strong adhesion, smooth solder flow

-

Packaging: Compact container for easy use

1 day delivery -

-

Sale!

-

Brand/Model: TNI-U 093D+

-

Power: 60W

-

Temperature Control: Variable (adjustable heat)

-

Heating Element: Durable, long-life

-

Handle: Anti-slip, heat-resistant ergonomic grip

-

Applications: PCB soldering, electronics repair, DIY, hobby work

-

Heating Speed: Fast heating with stable output

-

Safety: Overheating protection design

5 day deliveryQuick View

Wishlist

Variable Tni-u 60w Soldering Iron 093d+

$219 – $249Price range: $219 through $249Sold: 0Available: 6-

Brand/Model: TNI-U 093D+

-

Power: 60W

-

Temperature Control: Variable (adjustable heat)

-

Heating Element: Durable, long-life

-

Handle: Anti-slip, heat-resistant ergonomic grip

-

Applications: PCB soldering, electronics repair, DIY, hobby work

-

Heating Speed: Fast heating with stable output

-

Safety: Overheating protection design

5 day delivery -

-

-

Model: SE-930

-

Brand: Volder

-

Power: 30W

-

Voltage: 220–240V AC

-

Temperature Range: 100°C – 400°C

-

Tip Type: Replaceable, lead-free

-

Heating Element: Nickel-chromium

-

Indicator: Power-on light

-

Safety: CE & RoHS certified

-

Uses: Suitable for repair, assembly, and small electronics projects

-

Price Range in Pakistan: Around PKR 580 to 800

Quick View

Wishlist

Add to cart-

Model: SE-930

-

Brand: Volder

-

Power: 30W

-

Voltage: 220–240V AC

-

Temperature Range: 100°C – 400°C

-

Tip Type: Replaceable, lead-free

-

Heating Element: Nickel-chromium

-

Indicator: Power-on light

-

Safety: CE & RoHS certified

-

Uses: Suitable for repair, assembly, and small electronics projects

-

Price Range in Pakistan: Around PKR 580 to 800

-

-

-

Model: WEP 1502DD

-

Output Voltage: 0 – 15V DC (adjustable)

-

Output Current: 0 – 2A (max)

-

Display: Digital (LED)

-

Input Voltage: 220V AC (standard in Pakistan)

-

Type: Regulated bench power supply

-

Applications: Electronics repair, mobile repair, lab testing, DIY projects

-

-

Product Configuration

-

Software Installation: Install the dedicated XP8710 software on a Windows PC from the provided CD or website.

-

Connection: Connect the programmer to the PC using a USB cable. Ensure it is recognized by the software.

-

Power On: Switch on the programmer. The internal systems will initialize.

-

Chip Selection: In the software, select the target chip by entering its full part number (e.g., W25Q128JV).

-

Socket Adapter: Choose the correct socket adapter (e.g., DIP8, SOP8) that matches your chip’s package and pin count.

-

Chip Insertion:

-

Orientation is Critical. Align the chip’s notch or dot (marking Pin 1) with the notch or dot on the programmer’s socket.

-

Gently lock the chip into place.

-

-

Basic Operations:

-

Read: First, always READ the chip’s content and SAVE a backup file.

-

Load: Open the new firmware (.bin, .hex file) you want to write.

-

Program: Execute the program command. The software will often Erase, Program, and Verify automatically.

-

-

Standalone Mode: Load files onto a USB drive, plug it into the programmer, and use the touchscreen to select and run operations without a PC.

Quick View

Wishlist

Add to cartProduct Configuration

-

Software Installation: Install the dedicated XP8710 software on a Windows PC from the provided CD or website.

-

Connection: Connect the programmer to the PC using a USB cable. Ensure it is recognized by the software.

-

Power On: Switch on the programmer. The internal systems will initialize.

-

Chip Selection: In the software, select the target chip by entering its full part number (e.g., W25Q128JV).

-

Socket Adapter: Choose the correct socket adapter (e.g., DIP8, SOP8) that matches your chip’s package and pin count.

-

Chip Insertion:

-

Orientation is Critical. Align the chip’s notch or dot (marking Pin 1) with the notch or dot on the programmer’s socket.

-

Gently lock the chip into place.

-

-

Basic Operations:

-

Read: First, always READ the chip’s content and SAVE a backup file.

-

Load: Open the new firmware (.bin, .hex file) you want to write.

-

Program: Execute the program command. The software will often Erase, Program, and Verify automatically.

-

-

Standalone Mode: Load files onto a USB drive, plug it into the programmer, and use the touchscreen to select and run operations without a PC.

-

-

-

Brand: XT-MAX

-

Model: DT830L

-

Type: Digital Multimeter

-

Functions: DC/AC Voltage, DC Current, Resistance, Continuity, Diode & Transistor Test

-

Display: LCD with backlight

-

Status: Sold Out

-

-

Product Configuration

- Placement: Position the cleaner on your workbench within easy reach of your soldering station.

-

Sponge Preparation: Remove the sponge from the metal cup. Wet it thoroughly with water, then wring it out completely so it is damp but not dripping. Reinsert it into the metal cup.

-

Brass Wool: The container is pre-filled with fine brass wool. No preparation is needed. It is used dry.

-

Usage – Cleaning:

-

Brass Wool: Gently insert the hot soldering tip into the brass wool and rotate slightly. This removes excess solder and light oxidation without cooling the tip.

-

Damp Sponge: Wipe the tip across the damp sponge to remove flux residue and deeper carbon buildup. This slightly cools the tip.

-

-

Maintenance: Regularly empty the metal cup to discard solder balls and debris from the brass wool. Replace the sponge if it becomes burnt or worn out.

Quick View

Wishlist

Add to cartProduct Configuration

- Placement: Position the cleaner on your workbench within easy reach of your soldering station.

-

Sponge Preparation: Remove the sponge from the metal cup. Wet it thoroughly with water, then wring it out completely so it is damp but not dripping. Reinsert it into the metal cup.

-

Brass Wool: The container is pre-filled with fine brass wool. No preparation is needed. It is used dry.

-

Usage – Cleaning:

-

Brass Wool: Gently insert the hot soldering tip into the brass wool and rotate slightly. This removes excess solder and light oxidation without cooling the tip.

-

Damp Sponge: Wipe the tip across the damp sponge to remove flux residue and deeper carbon buildup. This slightly cools the tip.

-

-

Maintenance: Regularly empty the metal cup to discard solder balls and debris from the brass wool. Replace the sponge if it becomes burnt or worn out.